- This topic is empty.

-

AuthorPosts

-

2025-12-25 at 6:44 pm #11069

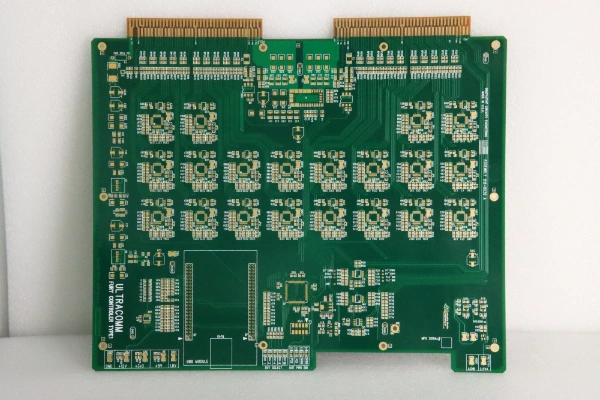

In advanced high-frequency electronics, the RF PCB board is the backbone that ensures signal quality, minimizes transmission loss, and supports stable high-speed communication. These boards are engineered specifically for handling RF signals and are indispensable in wireless systems, radar technologies, 5G infrastructure, and other high-bandwidth environments. Two of the most influential design pillars behind any RF PCB board are material selection and tight impedance control — both of which directly determine the stability, efficiency, and reliability of RF circuits. This article from SprintPCB explores why these factors are so important and how they shape high-frequency system performance.

RF PCB Board Material Selection — Why It Matters

The material used to manufacture an RF PCB board plays a decisive role in how effectively it can carry high-frequency signals. Physical properties such as dielectric constant, loss behavior, and thermal stability all contribute to the overall performance of the circuit. Choosing the wrong substrate can lead to excessive loss, unstable impedance, and degraded signal transmission — while the right choice enhances repeatability and electrical stability.

Dielectric Constant (Dk) & Loss Tangent (Df)

-

Dielectric Constant (Dk)

The dielectric constant represents how well a material stores electrical energy. In an RF PCB board, a lower and more uniform Dk helps reduce propagation delay and minimize signal attenuation. Consistency is vital — fluctuations in dielectric constant can distort high-frequency signals. -

Loss Tangent (Df)

The loss tangent measures the amount of signal energy lost as heat while traveling through the substrate. A low Df is essential for high-frequency RF circuits because excessive loss leads to attenuation, heat buildup, and degraded RF performance.

Common RF PCB Board Materials

Different materials serve different RF requirements:

-

FR-4

Suitable for general electronics, but not ideal for higher-frequency RF PCB board applications due to its higher Dk and loss values. It may still be acceptable for lower-frequency RF circuits. -

PTFE (Teflon)

Widely used in high-end RF designs thanks to its very low Dk and Df, making it excellent for antennas, radar systems, and satellite communication. Its thermal stability also improves long-term reliability. -

Ceramic-Filled Laminates

These materials deliver a balanced combination of thermal stability, low loss, and controlled dielectric properties, making them well-suited for microwave-level designs requiring strict impedance accuracy. -

Polyimide

Ideal for flexible RF PCB board structures. It offers strong thermal resistance and low-loss behavior, supporting bending applications without degrading RF performance.

Precision Impedance Control — Essential for RF PCB Board Signal Integrity

Controlling impedance is one of the most critical RF design tasks. When impedance is inconsistent, RF signals encounter reflections, distortion, and signal loss — which degrade system performance and efficiency. Precision impedance control ensures that RF signals move across the RF PCB board cleanly and predictably.

Why Impedance Stability Is So Important

Mismatched impedance results in:

-

Reflections along the trace

-

Additional noise

-

Attenuation and distortion

-

Potential malfunction in sensitive circuits

Consistent impedance protects signal clarity and transmission efficiency, which is vital for high-frequency operation.

Types of Impedance in RF PCB Board Design

Characteristic Impedance

This is the inherent impedance of a transmission line — such as a controlled-impedance RF trace. Common targets include 50Ω and 75Ω, widely used in antennas, RF connectors, and transmission networks. Accurate control prevents reflections and preserves energy transfer.

Differential Impedance

Used when two lines carry complementary signals — for example in Ethernet, USB, and other high-speed communication channels. Maintaining the correct differential impedance helps cancel noise and protect data integrity.

How Designers Achieve Precision Impedance Control

Reaching precise impedance values on an RF PCB board requires careful engineering:

Trace Geometry

Impedance is heavily influenced by:

-

Trace width

-

Distance to the reference plane

-

Spacing between differential pairs

Any deviation can cause mismatch — so exact calculations are essential.

Layer Stack-Up Design

The board stack-up defines the electrical environment surrounding each trace. Proper placement of ground and signal layers ensures stable impedance across the RF PCB board, particularly in multilayer designs.

Microstrip and Stripline Structures

-

Microstrip — outer-layer trace over a ground plane

-

Stripline — sandwiched between two reference planes

Stripline provides superior stability at very high frequencies.

Simulation and Modeling Tools

Modern RF design relies on impedance simulation software to:

-

Predict performance

-

Validate geometry

-

Prevent mismatch before fabrication

This reduces design iterations and risk.

Material Stability

Since dielectric constant affects impedance, substrates with consistent dielectric behavior — such as PTFE or ceramic-filled materials — are preferred for high-precision RF applications.

Challenges in RF PCB Board Material and Impedance Control

While these techniques improve performance, several challenges remain:

-

High-performance materials cost more than FR-4

-

Precise impedance tuning requires expertise and advanced tools

-

RF circuits generate heat, requiring strong thermal management

If heat is not controlled, it can change material properties and impact impedance — hurting signal integrity.

Final Thoughts

Selecting the right substrate and applying precision impedance control are two of the most important design considerations for any RF PCB board. Low-loss materials and stable dielectric properties help preserve high-frequency signals, while accurate impedance engineering eliminates reflections and distortion. When properly executed, these practices result in RF systems that deliver clean signal transmission, high reliability, and consistent performance in demanding fields such as 5G networking, radar sensing, and wireless communication.

Understanding — and correctly applying — these principles is key to building high-quality RF PCB board solutions for the next generation of high-frequency technologies.

https://www.sprintpcb.net/blogs/RF-PCB-Board-Material-Selection-and-Precision-Impedance-Control.html

https://www.sprintpcb.net/pcb/High-Frequency-PCB.html

http://www.sprintpcb.net

SprintPCB -

-

AuthorPosts

- You must be logged in to reply to this topic.