- This topic is empty.

-

AuthorPosts

-

2025-05-29 at 6:01 pm #9631

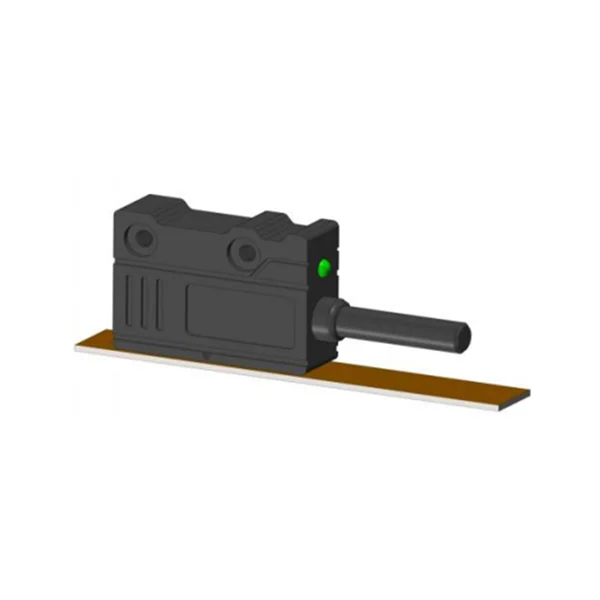

In the realm of high-precision motion control and position sensing, magnetic scale linear encoders have emerged as indispensable components for a wide range of industrial applications – from CNC machines and robotics to medical devices and semiconductor manufacturing. Among the various types, precision magnetic scale linear encoders stand out due to their robustness, resilience to environmental contaminants, and reliable accuracy over extended operational periods. In this blog post, ENX Enxiao, a high performance industrial encoder manufacturer, will share the production process of precision magnetic scale linear encoder for sale.

1. Precision Magnetic Scale Linear Encoder Material Preparation

1.1 Substrate Selection

The foundation of any magnetic scale is the substrate upon which magnetic materials will be deposited or embedded. Common materials include stainless steel strips, polymer composites, or anodized aluminum, depending on the end-use environment. The substrate must have minimal thermal expansion, high dimensional stability, and excellent surface flatness.

1.2 Magnetic Material Preparation

The magnetic properties of the encoder are imparted by ferromagnetic materials, typically based on rare-earth magnets such as Neodymium Iron Boron (NdFeB) or Samarium Cobalt (SmCo), or ferrite-based compounds for lower-cost applications. These materials are milled into fine powders or processed into tapes or sheets for subsequent application.

Before application, magnetic materials are conditioned for magnetic homogeneity and filtered to remove contaminants or non-uniform particles. Particle size distribution and magnetic flux density characteristics are critically controlled at this stage.

2. Magnetization and Pattern Encoding

2.1 Pattern Encoding Principles

A magnetic scale linear encoder functions by encoding position data into a magnetic pattern that is read by a sensor (readhead). The patterns are typically alternating north-south poles in a sinusoidal or square wave distribution. The pitch of the magnetic poles determines the resolution of the encoder.

2.2 Direct Magnetization Techniques

One of the most critical and technically demanding steps is the magnetization of the scale in a controlled pattern. This is typically achieved using multi-pole magnetizers equipped with high-precision coils that induce alternating magnetic poles at exact intervals.

Two dominant techniques are employed:

* Pulse Magnetization: Short, high-intensity magnetic fields are applied via a magnetic printing head, encoding the magnetic domains directly into the substrate.

* Laser-Assisted Magnetization: In emerging methods, laser energy is used to locally alter the magnetic properties of special thermosensitive materials, enabling finer control over magnetic pole pitch.

2.3 Pattern Verification

After encoding, the magnetic pattern is verified using magnetic field visualization tools, such as magneto-optical films or Hall effect sensor arrays. This step ensures that the pole pitch, field strength, and uniformity meet the design specifications.

3. Scale Assembly and Protection

3.1 Scale Cutting and Trimming

Once the magnetic pattern is applied and verified, the scale is trimmed to the desired lengths. Precision cutting machines – often CNC-guided – are used to avoid introducing mechanical stress or heat that could degrade magnetic alignment.

3.2 Protective Coating Application

Magnetic scales are exposed to harsh industrial environments, so protection is essential. A protective overlayer – such as epoxy resin, polyimide film, or UV-cured acrylic – is applied over the magnetic scale to shield it from mechanical abrasion, moisture, and chemical exposure.

In high-precision applications, optically clear and low-friction coatings are selected to reduce interference with the readhead's optical or magnetic sensor elements. The coating process is typically carried out in a cleanroom to prevent particulate contamination.

3.3 Backing and Adhesive Integration

The prepared scale is affixed with industrial adhesives or backing tapes for final assembly onto machines or enclosed within a hermetic housing for long-term durability. Some designs include flexible scale assemblies embedded in polymer tracks for curved or dynamic installations.

4. Readhead Production and Integration

4.1 Sensor IC Fabrication

The readhead contains a magnetoresistive (MR), Hall-effect, or GMR (Giant Magnetoresistance) sensor array fabricated on a silicon die. These integrated circuits are manufactured through semiconductor processes including photolithography, doping, and etching.

The sensor arrays are precisely aligned with signal processing circuits that convert magnetic field variations into usable analog or digital output formats (e.g., quadrature signals or absolute position data).

4.2 Signal Conditioning and Processing

Signal fidelity is critical for achieving high-resolution output. Signal conditioning circuits apply amplification, filtering, interpolation, and error correction. In advanced encoders, digital signal processors (DSPs) are embedded to perform real-time compensation for temperature drift, signal noise, or scale deformation.

4.3 Mechanical Integration

The readhead assembly is housed in a compact enclosure with features such as:

* Thermal isolation structures to minimize drift.

* Integrated cable management and EMI shielding.

* Mounting alignment guides for proper installation relative to the magnetic scale.

In many designs, the readhead and scale operate with a non-contact gap (typically 0.1 to 1.0 mm), so precision in assembly is paramount.

5. Calibration and Quality Assurance

5.1 Factory Calibration

Before shipment, each encoder unit undergoes multi-point calibration against a reference linear scale traceable to national metrology standards (e.g., NIST or PTB). This ensures the output resolution, accuracy (often ±1 μm or better), and repeatability meet the product specifications.

Calibration involves running the readhead across the entire length of the scale under simulated working conditions, collecting real-time data and generating error compensation curves stored in EEPROMs within the readhead.

5.2 Environmental Testing

Precision magnetic encoders must withstand a wide range of environmental conditions. Hence, each unit is tested for:

* Thermal cycling from -40°C to +85°C.

* Shock and vibration resistance in accordance with IEC/ISO standards.

* EMC compliance to ensure signal integrity in electrically noisy environments.

* Ingress Protection (IP) rating for dust and moisture sealing.

5.3 Final Inspection and Packaging

Final inspection involves visual checks, signal integrity verification, and dimensional inspection. Certified units are serialized and logged for traceability. Packaging is performed in ESD-safe, moisture-barrier bags to prevent damage during transit.

Conclusion

The manufacturing of a precision magnetic scale linear encoder is a symphony of materials science, magnetic engineering, semiconductor technology, and meticulous quality control. Every phase – from selecting magnetic materials to encoding precise pole patterns and fabricating sensor ICs – requires extreme attention to detail and robust process controls. As the demand for high-performance motion control systems continues to grow, advances in this manufacturing domain will remain critical for pushing the boundaries of industrial automation and mechatronic innovation.

Whether deployed in aerospace positioning systems or high-speed printing machinery, precision magnetic encoders are a testament to the intersection of physics, engineering, and craftsmanship.

http://www.enxsensors.com

ENX Enxiao -

AuthorPosts

- You must be logged in to reply to this topic.