- This topic is empty.

-

AuthorPosts

-

2025-08-19 at 9:20 am #10247

In today's manufacturing and packaging industries, protecting products from external damage, contamination, and scratches is essential. One of the most effective ways to safeguard various materials and products is through the use of PE protective film (Polyethylene protective film). This versatile and reliable material provides a shield for a variety of surfaces, including plastics, metals, glass, and more, ensuring they remain in pristine condition throughout production, handling, and transportation.In this article, Peiyang will explore the key considerations for using PE protective film. Whether you're in the construction, automotive, electronics, or packaging industry, understanding the critical role of PE protective film will help you make informed decisions about how it can benefit your business operations.

What is PE Protective Film?

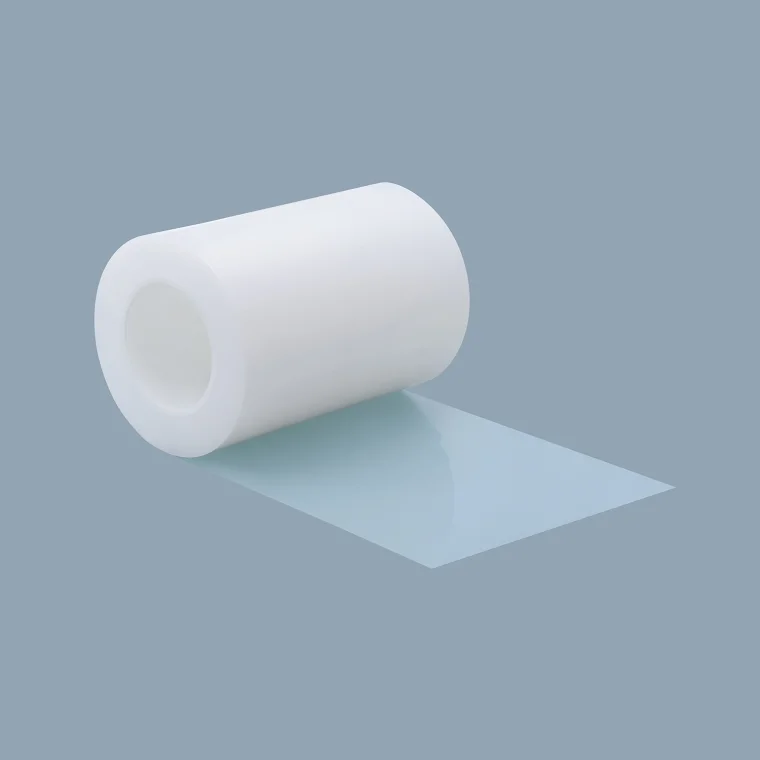

PE protective film is a thin, flexible layer made from polyethylene (PE), a lightweight yet durable plastic material. This type of protective film is designed to adhere to various surfaces, providing a shield that protects the material beneath from dirt, moisture, scratches, abrasion, and other forms of physical damage. PE protective film serves as an effective barrier to keep products clean, safe, and in pristine condition during manufacturing, transportation, and storage.

Available in both clear and colored options, PE protective film can be customized to meet specific needs, offering a range of thicknesses, adhesive strengths, and durability levels. One of the key benefits of PE protective film is its ability to be easily applied and removed, without leaving any residue behind. This makes it especially useful for industries that require frequent handling or temporary protection, such as packaging, electronics, and automotive manufacturing.

Due to its versatility, PE protective film is widely utilized across various industries, including packaging, electronics, construction, automotive, and more. It protects sensitive surfaces like plastic, metal, glass, and painted finishes, ensuring they remain in top condition throughout the supply chain process. Whether it's protecting the shiny surface of a new appliance, preventing scratches on window panels, or safeguarding electronic components, PE protective film plays a crucial role in maintaining the integrity and appearance of a wide range of products.

Considerations When Choosing PE Protective Film

1. Material Compatibility

When choosing a PE protective film, it's essential to ensure that it is compatible with the material you are protecting. Not all protective films work well with every surface, and improper selection can lead to issues such as poor adhesion or even surface damage. For instance, PE protective film designed for metal surfaces should offer strong adhesion without leaving residue or damaging the surface finish. For glass, the film must adhere well without causing scratches or streaks, while for plastic, it's important that the film doesn't cause discoloration or degradation.

Choosing the right PE protective film ensures that the protective qualities of the film—such as resistance to abrasion or UV exposure—are fully utilized while preventing any negative impact on the surface underneath. Always consider the specific material properties and select a PE protective film that is designed to work seamlessly with your item's surface, whether it's for storage, shipping, or processing.2. Adhesive Strength

The adhesive strength of the PE protective film is another key factor to consider. If you're working with sensitive surfaces, such as glossy finishes or delicate materials, you'll need a PE protective film with a lighter adhesive that won't leave residue or cause surface damage upon removal. On the other hand, if you're protecting a more durable surface, like metal or wood, you might require a stronger adhesive that ensures the film stays securely in place during transit or handling.

The right balance of adhesive strength is crucial because too strong of an adhesive can be difficult to remove and may damage the surface, while too weak of an adhesive may cause the film to peel off prematurely. Therefore, choosing a PE protective film with the correct adhesive strength for your specific application ensures a safe, effective, and residue-free protection.3. Thickness and Durability

The thickness of the PE protective film is a significant factor in determining the level of protection it provides. Thicker films offer enhanced protection against physical damage, such as scratches, dents, or abrasion, which makes them ideal for products that will face rough handling or transportation. Conversely, thinner PE protective films are better suited for protecting delicate surfaces where a more flexible, non-bulky solution is needed. For example, thin films are perfect for protecting electronics, where a bulkier film could interfere with functionality or appearance.

Additionally, the durability of the PE protective film affects how well it performs over time. For long-term protection, you should opt for a thicker and more durable PE protective film, especially if the material will be exposed to rough conditions or outdoor elements. A well-chosen film ensures that your product remains pristine during the entire handling and storage process.4. Environmental Conditions

It's essential to consider the environmental conditions the product will face when selecting a PE protective film. If your product is going to be exposed to high temperatures, humidity, or UV rays, you need a PE protective film that is designed to withstand these conditions. For example, some PE protective films are UV-resistant, which helps prevent degradation caused by sun exposure, making them ideal for outdoor applications or extended storage in sunny areas.

Likewise, films that are specifically designed for high-temperature environments will maintain their adhesion and protective properties without melting or losing effectiveness. Ensuring that the PE protective film is rated for the specific environmental conditions your product will encounter will provide long-lasting protection and prevent any performance failures.5. Ease of Removal

Another important consideration when choosing a PE protective film is how easily it can be removed. Some films are designed for easy removal, leaving no residue behind and not damaging the underlying surface. These are ideal for temporary applications, such as during manufacturing or packaging, where the film will need to be taken off without leaving any sticky traces.

However, if the PE protective film is intended to stay on for a long time or throughout the product's use, it may need to be more robust, which can sometimes make removal more challenging. Always ensure that the PE protective film you choose matches the removal needs of your project—whether you need quick and clean removal or longer-term protection. Selecting the right film ensures that the product remains undamaged and residue-free once the protection is no longer needed.PE protective film is an indispensable tool across a wide range of industries, offering protection against scratches, dirt, dust, and moisture while maintaining the integrity of the product beneath. Its versatility, ease of application, and customization options make it the go-to solution for manufacturers, packagers, and installers. Whether you're in construction, automotive, electronics, or packaging, using PE protective film helps ensure that your products remain in excellent condition throughout the production and shipping process. By selecting the right type of PE protective film, you can safeguard your products and enhance customer satisfaction while reducing costs associated with damage and repairs.

https://www.opticaladhesives.com/PE-Protection-film

http://www.opticaladhesives.com

Suzhou PeiYang New Material Technology Co. Ltd -

AuthorPosts

- You must be logged in to reply to this topic.