- This topic is empty.

-

AuthorPosts

-

2025-09-09 at 2:22 pm #10339

Introduction – Why Modern Architecture Demands Energy Efficiency

In today’s architectural landscape, energy efficiency and sustainability are no longer optional—they are essential. Thermal performance, insulation, and comfort are key considerations for modern buildings, from residential high-rises to commercial complexes. Traditional aluminum, while strong and lightweight, conducts heat and cold readily, which can lead to higher energy consumption for heating and cooling.

Enter thermal break aluminum, a solution engineered to minimize heat transfer while maintaining aluminum’s structural benefits. At KaiMeiDa Aluminum, we specialize in high-performance thermal break aluminum profiles that meet national standards and provide architects and builders with superior energy-efficient solutions.

Comparative Performance Analysis

Thermal Break Aluminum vs Standard Aluminum:

-

Thermal Conductivity: Thermal break aluminum incorporates an insulating material between aluminum sections, drastically reducing heat transfer. With appropriate glass, the thermal transmittance can reach ≤2.7 W/m²·K, enhancing indoor comfort. Standard aluminum, in contrast, offers minimal insulation, leading to energy loss.

-

Energy Savings: Buildings with thermal break aluminum profiles require less heating in winter and cooling in summer, lowering overall energy costs.

-

Indoor Comfort: By preventing cold or heat bridging, thermal break aluminum creates stable indoor temperatures and reduces condensation.

Durability and Maintenance Advantages

Thermal break aluminum profiles are not only energy-efficient—they are also highly durable and low-maintenance:

-

High Longitudinal Anti-Shearing Value: ≥24 N/mm, ensuring structural integrity in high-rise and heavy-duty applications.

-

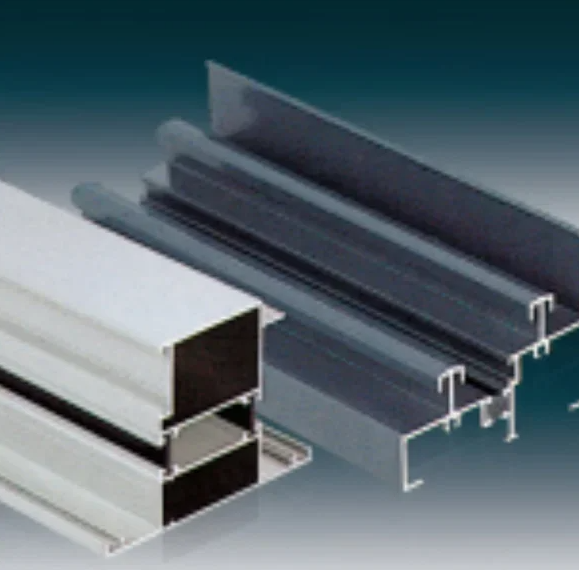

Surface Finishes: Options include anodizing, electrolytic coating, powder coating, PVDF coating, and timber texture, providing both aesthetic flexibility and corrosion resistance.

-

Environmentally Friendly: The insulation system reduces energy demand and contributes to sustainable building practices, making it suitable for green-certified projects.

Architectural Applications

Thermal break aluminum is highly versatile and suitable for a range of architectural projects:

-

Windows and Sliding Doors: Enhanced insulation without compromising structural strength.

-

Curtain Walls and Facades: Energy-efficient exterior surfaces with customizable finishes.

-

Office and Industrial Profiles: Durable profiles that meet demanding architectural standards.

With KaiMeiDa Aluminum’s advanced production lines, including anodic oxidation, powder coating, wood grain transfer, and electrophoretic painting, architects can achieve precise, high-quality profiles tailored to their projects.

Conclusion & Call to Action – Superior Benefits of KaiMeiDa Thermal Break Aluminum

In comparison to standard aluminum, thermal break aluminum provides unmatched energy efficiency, indoor comfort, durability, and design flexibility. By incorporating thermal breaks and high-performance coatings, KaiMeiDa Aluminum ensures that modern buildings are not only visually appealing but also sustainable and cost-effective over time

http://www.jxkmdly.com

Jiangxi Kaimeida Aluminum Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.